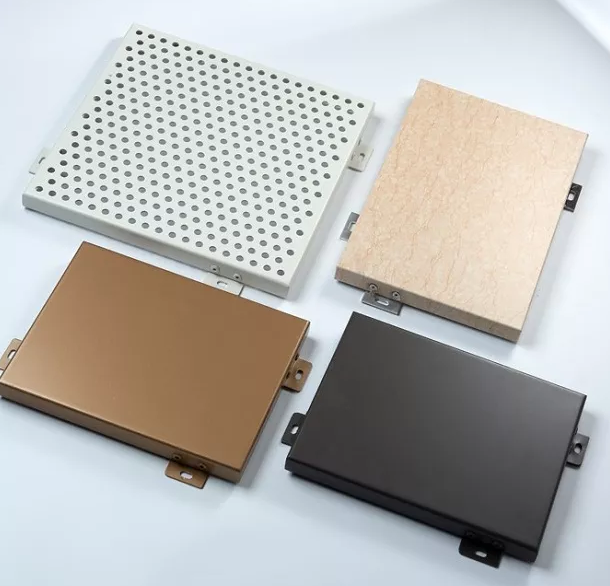

Aluminum Composite Panel

Since 2012, MC BOND has delivered high-quality Aluminum Composite Panels globally. We welcome your cooperation and look forward to supporting your projects with premium ACP.

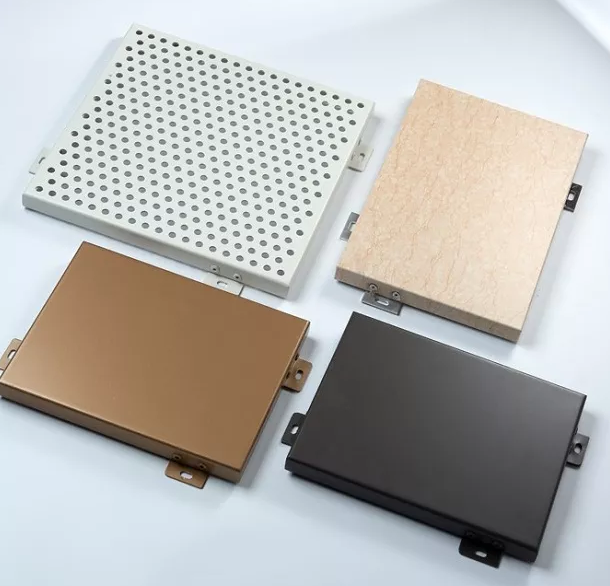

Product Overview of Aluminum Composite Panel

What is an Aluminum Composite Panel (ACP/ACM)?

Aluminum Composite Panel (ACP), also called Aluminum Composite Material (ACM), is a three-layer sheet composed of two coated aluminum skins bonded to a core (typically PE, HDPE or FR). At MCBOND, our standard construction uses a 0.5 mm aluminum alloy skin bonded to a 3 mm HDPE core (for standard panels) – giving excellent flatness, durability and lightweight performance.

MCBOND’s Aluminum Composite Panel Expertise & Production Capacity

Since 2012, MCBOND has specialised in metal composite panels including aluminum composite panels. Located in Taizhou, Zhejiang, China, we are equipped with 3 high-speed production lines (including a German-technology co-extrusion line) capable of producing up to 8,000 m² ACP per day, with maximum width up to 2,000 mm and thickness up to 20 mm. We export globally, serving North America, Latin America, Europe, Asia and Africa.

Key Advantages of Aluminum Composite Panels

Lightweight Yet Rigid Construction

ACP/ACM panels weigh up to half the weight of solid aluminum sheets, yet maintain excellent rigidity and flatness — simplifying installation and reducing structural load.

Superior Weather, UV & Corrosion Resistancen and reducing structural load

With PVDF or PE coatings, MCBOND panels offer long-term colour retention and surface protection against weather, UV, acid/alkali, and corrosion.

Fire Safety Options (FR/A2 Core)

For high-rise buildings, public facilities or signage with fire-safety demands, our FR-core and A2-core panels meet key international standards.

Surface Flatness & Printability

Ultra-smooth surface enables high-quality digital printing, enabling crisp signage, advertising, and architectural graphics.

Eco-Friendly & Recyclable Materials.

The aluminum skins are 100 % recyclable, aligning with sustainable building and design strategies.

Technical Specifications of MCBOND ACP/ACM

Panel Structure & Core Options

Skin: 0.12-0.50 mm aluminum alloy; Core: HDPE, FR (fire-retardant) or A2 non-combustible;

Construction: two aluminum sheets + core

Standard Sizes, Thickness & Formats

Formats: 1220 × 2440 mm, 1250 × 3050 mm, 1500 × 3050 mm;

Thickness: 3 mm, 4 mm, 5 mm, 6 mm (others on request).

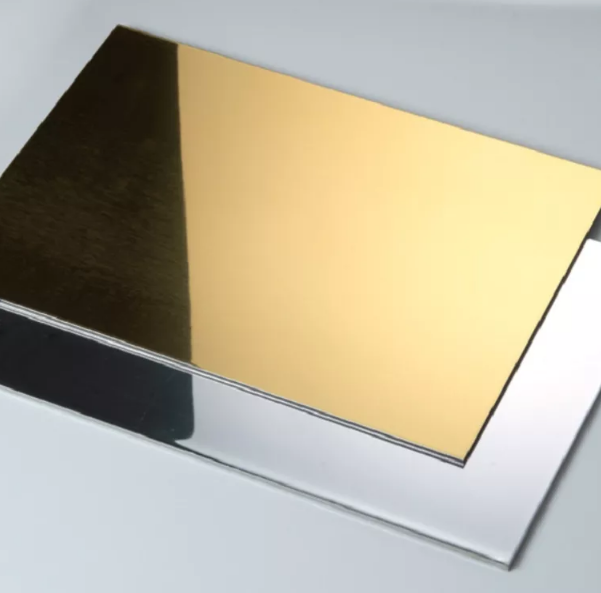

Surface Coatings (PE, PVDF, Anodized)

Coatings: PE for general use; PVDF for high durability exterior use;

Anodized finishes for special metallic textures.

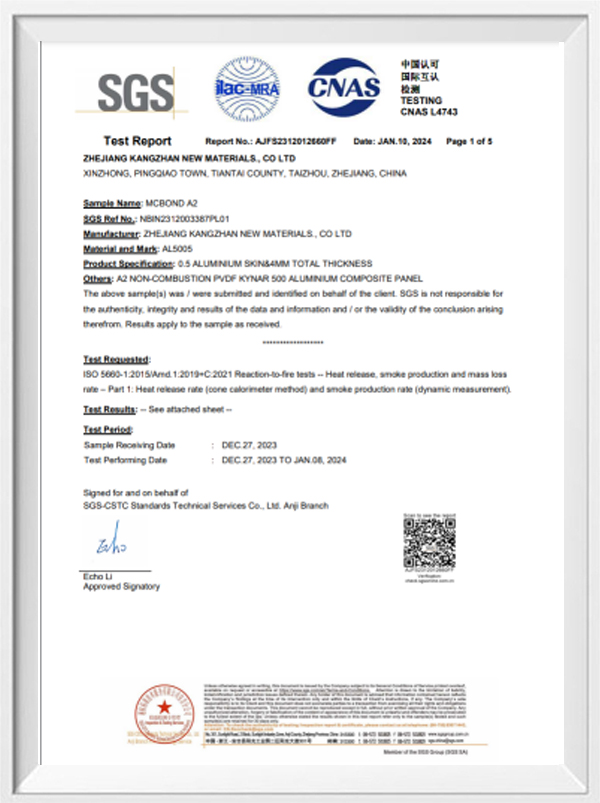

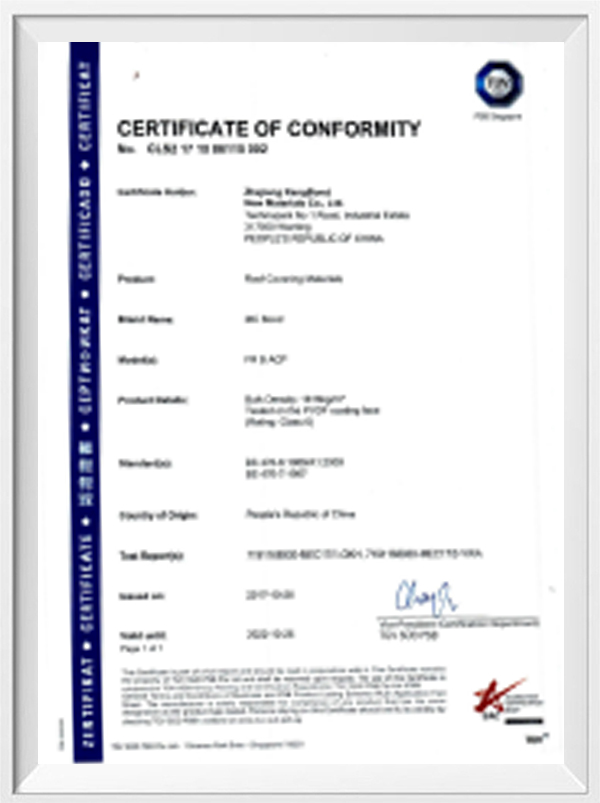

Certifications & Quality Assurance

MCBOND’s ACP/ACM panels are tested to ASTM, EN, ISO standards, and factory follows 4-point check quality process from raw material to post-production inspection.

Contact Us

Applications of Aluminum Composite Panels

Services & Support for ACP/ACM Buyers

Custom Cutting & Fabrication Services

MCBOND offers CNC cutting, grooving, bending and edge finishing services for tailored panel sizes and shapes.

Technical Assistance & Installation Guidance

Engineering support and installation instructions help clients ensure correct usage and avoid issues.

Color Matching & Texture Customization

Support for Pantone colour matching, metallic, stone, mirror finishes to meet design requirements.

Global Delivery & Inventory Support

Worldwide shipping, reliable stock and fast delivery ensure projects stay on schedule.

Contact Us

MC BOND, a global supplier since 2012, provides reliable Aluminum Composite Panels with exceptional strength and finish. Enhance your facade or signage project with our premium ACP.

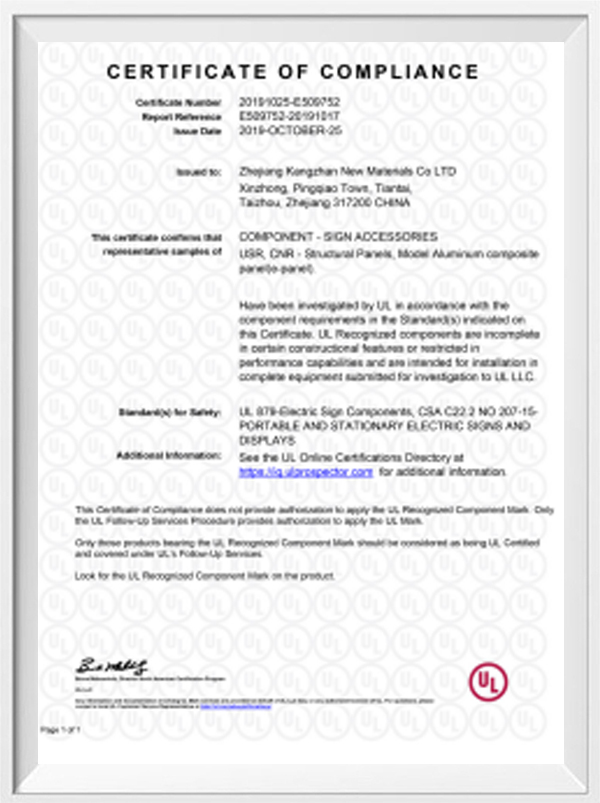

Our Certificate

MCBOND's products have not only passed the CTC quality certification of the National Building Materials Testing Center, but also passed the CE EU, Swiss SGS, Singapore PSB, Australian NATA, and American ASTM standard tests. The company has in-depth cooperation with many well-known domestic and foreign suppliers such as DuPont, PPG, BECKER, RHEINZINK, China Aluminum Corporation, China Steel Corporation, and Sinopec.

FAQs – Aluminum Composite Panel Questions

Fire-retardant core (FR) and non-combustible core (A2) versions meet ASTM E84, EN

Yes, our digital-printing Grade ACM has ultra-flat surface and high ink adhesion.

Related Blogs

-

Are you planning an outdoor project and wondering if galvanized steel panels are the right choice? These panels are steel sheets coated with zinc to prevent rust and corrosion. Choosing the right material is crucial for long-lasting outdoor structures. In this post, you'll learn about the benefits o

Are you planning an outdoor project and wondering if galvanized steel panels are the right choice? These panels are steel sheets coated with zinc to prevent rust and corrosion. Choosing the right material is crucial for long-lasting outdoor structures. In this post, you'll learn about the benefits o

Keep In Touch With Us

We can customize any color according to your requirements, offering free color matching and free samples to help you confirm the perfect finish for your project.

Mob:+86-576-83060887\+86-15868315794

E-mail:maplechen@mcbond.cn

English

English