Views: 0 Author: Site Editor Publish Time: 2026-02-10 Origin: Site

Can an ACM Panel fail without visible damage? The answer often hides inside the bond layer. In this article, you will learn how adhesive quality influences ACM Panel durability, controls resistance to heat and moisture, and prevents early peeling or delamination.

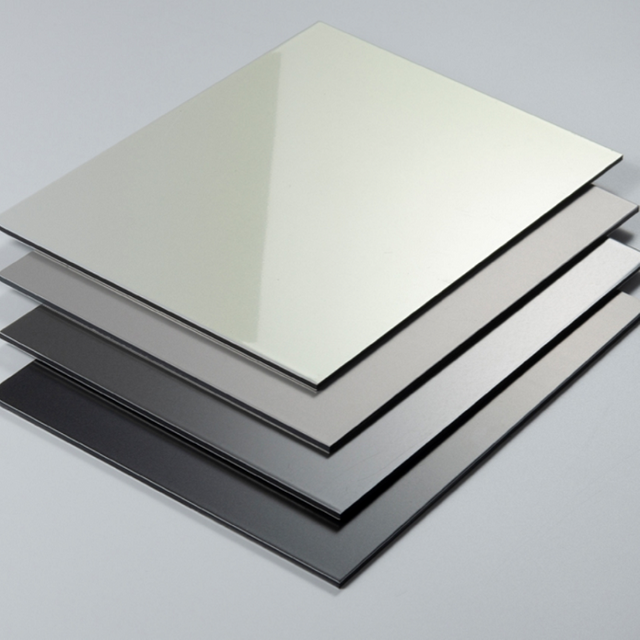

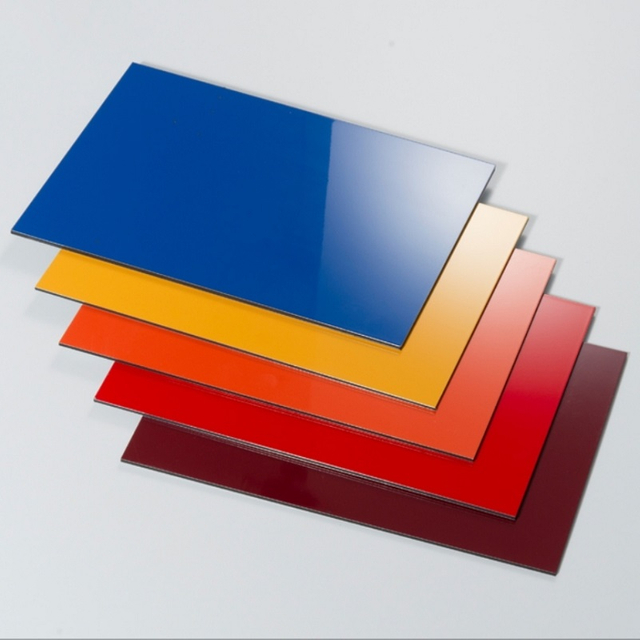

An ACM Panel is not held together by chance. It relies on a carefully selected adhesive layer to bond two aluminum skins to a polymer core, forming a stable sandwich structure. This bonding process allows the panel to behave as a single unit rather than three separate materials.

When pressure and heat are applied during lamination, the adhesive flows and locks the layers together, creating consistent thickness and strong internal cohesion. Because the adhesive spreads evenly across the surface, it supports flatness and prevents localized stress points that could weaken the panel over time.

Key structural benefits provided by adhesive bonding include:

● Continuous contact between aluminum skins and the core, which enhances rigidity without adding weight.

● Improved resistance to bending and warping compared to loosely assembled panels.

● Long-term stability that supports consistent panel thickness and edge quality during fabrication.

Structural Aspect | Role of Adhesive in an ACM Panel |

Panel rigidity | Creates unified load-bearing behavior |

Flatness control | Eliminates gaps and uneven pressure |

Weight efficiency | Replaces heavy mechanical connectors |

Dimensional stability | Manages expansion and contraction |

Mechanical fasteners such as screws or rivets work by concentrating force at specific points, while adhesives distribute stress across the entire ACM Panel surface. This difference has a direct impact on durability. When loads from wind, handling, or vibration act on a panel, adhesive bonding spreads those forces evenly, reducing the risk of cracking, denting, or surface distortion.

Mechanical fasteners, by contrast, can create localized deformation and visible defects, especially on large-format panels.

Another advantage of adhesive bonding is surface integrity. Because there are no penetrations through the aluminum skins, the ACM Panel retains a clean appearance and continuous protective coating. This improves corrosion resistance and reduces maintenance concerns.

Peel strength sits at the core of how an ACM Panel holds together over time. It describes how strongly the aluminum skins remain bonded to the core when force pulls them apart. In real use, panels face bending, wind pressure, transport handling, and fabrication stress. A higher 180° peel strength allows the adhesive layer to resist these forces evenly, keeping edges tight and surfaces intact.

Strong peel strength reduces visible failure risks. It prevents edge separation during cutting, folding, or installation. It also helps the ACM Panel stay flat after years of service, even when exposed to repeated movement or load changes. This is why peel strength testing often becomes a key indicator of internal panel quality rather than just surface appearance.

Peel Strength Level | Impact on ACM Panel Durability |

Low peel strength | Higher risk of edge lifting and delamination |

Medium peel strength | Acceptable short-term performance |

High peel strength | Long-term structural stability and clean edges |

Heat resistance plays a major role during ACM Panel manufacturing, especially when surface coatings require elevated curing temperatures. During PE or PVDF coating cycles, adhesives must stay stable and flexible. If they soften too much or lose bonding strength, internal separation may occur before the panel ever reaches the job site. Thermal stability allows the adhesive to maintain its grip as aluminum skins expand and contract under heat.

During post-processing, such as bending or CNC routing, residual heat can build up locally. A heat-resistant adhesive absorbs this stress and distributes it across the panel. This behavior protects the core bond line and keeps the ACM Panel from developing weak zones.

Key heat-related benefits of high-quality adhesives include:

● Stable bonding during high-temperature coating and curing stages.

● Reduced risk of internal slip between layers during fabrication.

● Consistent panel behavior across different thicknesses and finishes.

Moisture challenges every ACM Panel used outdoors or in humid environments. Adhesives must resist water absorption and maintain bonding strength when exposed to humidity swings. Poor-quality adhesives allow moisture to penetrate the bond line, which can lead to bubbling, glue-line opening, or gradual loss of adhesion. Over time, this damage becomes visible on the panel surface and edges.

A moisture-resistant adhesive acts as a protective barrier inside the ACM Panel. It keeps the aluminum skins firmly bonded even when weather conditions change rapidly. This internal stability supports long-term performance in facades, signage, and exterior cladding where panels face rain, heat, and cold cycles throughout the year.

Common moisture-related risks avoided by quality adhesives:

● Surface blistering caused by trapped moisture.

● Bond weakening in humid or coastal climates.

● Progressive delamination during seasonal changes.

Adhesives change as an ACM Panel ages. UV exposure, thermal cycling, and long-term load gradually test the flexibility and strength of the bond line. High-quality adhesives are designed to age slowly, retaining elasticity and bonding strength as the panel matures. This controlled aging helps panels maintain performance far beyond initial installation.

Before any adhesive touches an ACM Panel, the aluminum surface must be prepared correctly. Cleaning removes oils, rolling residues, and dust left from aluminum processing. Degreasing helps the adhesive contact pure metal rather than contaminants. Chemical pretreatment then forms a thin, stable conversion layer, which improves adhesive grip and consistency. When this step runs under controlled conditions, the adhesive spreads evenly and bonds more predictably across the panel surface.

Insufficient pretreatment often causes hidden problems. Adhesives may appear strong at first, yet fail later under heat or moisture exposure. Weak chemical layers allow separation to start at edges or corners, then grow inward. Over time, these issues show up as peeling or surface distortion.

Pretreatment Step | Influence on ACM Panel Bonding |

Cleaning | Removes barriers to adhesive contact |

Degreasing | Improves wetting and bond uniformity |

Chemical treatment | Creates stable bonding interface |

The core material plays a direct role in how adhesives perform inside an ACM Panel. PE cores bond easily and offer stable interaction with most polymer bonding films. FR and A2 cores introduce fillers and mineral content, which change heat flow and bonding behavior. Adhesives must match these materials, or internal stress can build during lamination.

Problems arise when recycled or inconsistent core materials enter production. Mixed polymers melt unevenly, so the adhesive cannot fuse properly across the full panel width. This leads to weak zones inside the ACM Panel, even when the surface looks smooth. Over time, those weak zones reduce durability and shorten service life.

Key material-related risks include:

● Uneven bonding caused by inconsistent core composition.

● Reduced peel strength due to poor adhesive-core interaction.

● Higher failure rates under thermal cycling or load changes.

Polymer bonding films have a specific orientation. One side bonds to aluminum, the other to the core. If orientation is reversed, the adhesive may partially bond yet lack long-term strength. Proper melting control also matters. The film must reach full activation temperature, allowing it to flow and fuse without degrading. When heat or pressure falls short, a pseudo-composite forms, where layers stick temporarily but separate later.

Good melting control supports reliable ACM Panel durability. It allows the adhesive to penetrate micro-structures on both surfaces, locking layers together. Customers benefit from panels that stay intact during fabrication, transport, and years of service.

Testing reveals what visual inspection cannot. Peel and adhesion tests measure how well the adhesive resists separation under controlled force. These results help predict how an ACM Panel will behave under wind load, bending, and thermal movement. When test values stay consistent, customers gain confidence in long-term durability rather than short-term appearance.

Peel testing also highlights process stability. If results vary across batches, it signals issues in pretreatment, adhesive application, or lamination control. Reliable testing data supports steady production quality and fewer failures in the field.

Test Focus | What It Reveals About ACM Panel |

Peel strength | Resistance to delamination |

Adhesion consistency | Process stability |

Edge performance | Long-term bond reliability |

Adhesive performance depends on controlled production conditions. Temperature affects how the adhesive flows and activates. Pressure ensures full contact between layers. Line speed controls how long materials stay in the bonding zone. When these factors stay balanced, the ACM Panel forms a uniform internal structure.

Quality inspection adds another safety layer. Visual checks, sample testing, and process monitoring catch defects before panels leave the factory. This approach reduces hidden bonding issues and supports predictable ACM Panel durability across different applications and environments.

In exterior projects, an ACM Panel faces constant stress from wind load, temperature shifts, and long-term weather exposure. Adhesive quality determines how well the aluminum skins stay bonded to the core as these forces repeat every day. A stable adhesive layer spreads wind pressure across the full panel surface instead of letting stress concentrate at edges or fixing points. This helps large-format ACM Panels remain flat and secure on building facades, even at height or in open, windy locations.

Thermal movement is another daily challenge. Aluminum expands and contracts, sometimes sharply between day and night. High-quality adhesives absorb and redistribute this movement, reducing internal tension.

Exterior Condition | Role of Adhesive in ACM Panel |

Wind load | Distributes force evenly |

Temperature change | Absorbs expansion movement |

Weather exposure | Maintains long-term bond integrity |

Fire-rated ACM Panels, including FR and A2 core panels, place higher demands on adhesive performance. These panels often operate in regulated environments where bond failure is not acceptable. Adhesives must remain stable around elevated temperatures without softening or releasing layers. If the adhesive weakens too early, panel integrity may drop before the core reaches its designed fire performance level.

In safety-critical uses, bond reliability supports predictable behavior under stress. A well-matched adhesive-core system keeps aluminum skins attached during thermal exposure, helping the ACM Panel perform as intended. This consistency matters in public buildings, high-rise structures, and areas governed by strict fire safety standards.

Key adhesive expectations for fire-rated panels include:

● Stable bonding at elevated temperatures.

● Compatibility with mineral-filled FR and A2 cores.

● Controlled aging under heat exposure.

Indoor and decorative uses may seem less demanding, yet adhesive quality still shapes performance. In signage and display panels, flatness directly affects visual quality and print clarity. Adhesives help maintain smooth surfaces by preventing subtle waviness or internal slip between layers. This supports clean edges and consistent appearance during cutting, routing, and mounting.

Controlled indoor environments reduce moisture and temperature extremes, but long-term bond stability still matters. Panels may hang for years without adjustment. A stable adhesive ensures the ACM Panel keeps its shape and finish, preserving visual impact and reducing maintenance needs across interior and signage applications.

Adhesive quality shapes how an ACM Panel performs over time. Strong bonding supports peel strength, heat resistance, and weather durability. Good manufacturing control prevents hidden delamination and aging failures. MC BOND ACM Panel solutions focus on stable bonding, consistent quality, and long service value.

A: Adhesive quality holds the ACM Panel layers together and prevents peeling or delamination.

A: High peel strength helps an ACM Panel resist edge separation during use.

A: Heat-stable adhesives protect the ACM Panel during coating and fabrication.

A: Yes, weak adhesives allow moisture and temperature changes to damage an ACM Panel.

A: Good adhesive quality extends ACM Panel durability and reduces maintenance needs.