| Availability: | |

|---|---|

| Quantity: | |

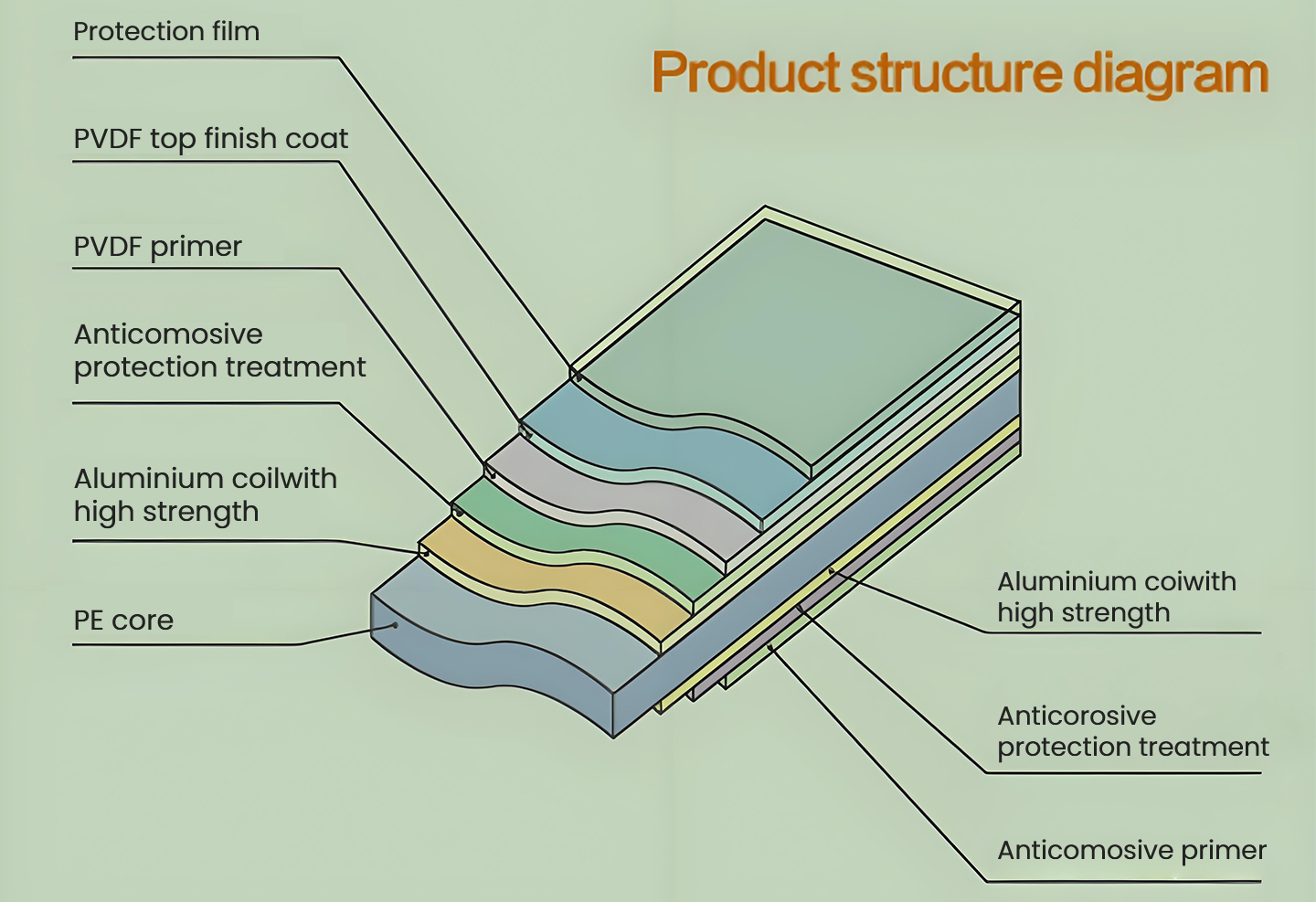

Cladding Aluminium Composite Panels PVDF Painting is an aluminum panel coated with PVDF (Polyvinylidene fluoride), featuring a high gloss finish that is achieved through a specialized coating process. The PVDF coating is applied using advanced techniques to ensure a uniform and smooth surface, resulting in a high gloss appearance that reflects light effectively. PVDF coating is known for its excellent weathering characteristics, making this panel a durable and visually appealing option for architectural applications. The aluminum base provides the panel with strength and formability, allowing it to be shaped into various designs while maintaining its structural integrity.

| Width | 1220mm, 1250mm, 1500mm |

| Length | Any size, recommend 2440mm, 3050mm, 4050mm, 5800mm |

| Panel Thickness | 3mm~6mm, recommend 4mm |

| Alu.Skin Thickness | 0.21mm~0.50mm, recommend 0.30mm and 0.40mm; |

| Alu. Alloy | AA3003(Different Grade Available) |

| Surface Treatment | PVDF/FEVE/NANO |

| Colors | Refer to Color Chart for more options |

| Others | Accept custom color and sizes |

Polyvinylidene fluoride that is also known as PVDF in short, is a type of fluorocarbon polymer resin used in architectural coating. PVDF coating is one of the preferred architectural coatings due to its excellent weathering characteristic of fluorinated materials

| Testing Item | Standard | Result |

| Coating Thickness | ASTM D1400 | 5µm Primer, 20µm Topcoat |

| Gloss | ASTM D523@60º | 23-35 |

| Pencil Hardness | ASTM D3363 | HB-H |

| Flexibility,T-Bend | ASTM D4145 | 1T-Bend; No pick-off |

| Solvent Resistance | ASTM D5402 | 100+ MEK double rubs |

| Adhesion | ASTM D3359 | No Adhesion Loss |

| Reverse Impact 1/16” Crosshatch | ||

| Reverse Impact | ASTM D2794 | 5.0J (0.6mm), No pick off |

| Acid Resistance | ASTM D1308 | No effect |

| Alkali Resistance | ASTM D1308 | No effect |

| Humidity Resistance | ASTM D714 | Passes 4000 hrs. |

The standard panel thickness is 4mm, with options of 3mm, 5mm, and 6mm. The coil thickness is 0.7/0.5mm as standard, with alternatives like 0.5/0.4mm and 0.5/0.5mm. The panel width is 1220mm standard, with options of 1250mm, 1500mm, and 1550mm, and the length is 2440mm standard, up to 5800mm. This wide range of specifications ensures that the panel can be used in a variety of architectural designs, from small feature walls to large curtain walls.

The PVDF coating provides excellent weather resistance, including resistance to ultraviolet rays, moisture, and chemicals. This ensures the panel maintains its high gloss finish and performance over a long period, even in harsh environmental conditions such as coastal areas with high salt content in the air or industrial areas with chemical pollutants. The coating also has good color retention, preventing fading over time.

The high gloss surface adds a modern and elegant touch to buildings, enhancing their visual appeal. It reflects light, making the building appear brighter and more spacious, and can also mirror the surrounding environment, creating a harmonious blend with the surroundings. The smooth surface is easy to clean, maintaining its glossy look with minimal effort.

This panel is widely used in high-end architectural projects. It is suitable for curtain walls of commercial buildings, hotels, and office towers, where a sleek and shiny appearance is desired to make a strong visual statement. It can also be used in interior decoration, such as feature walls and ceilings in luxury retail stores and restaurants, adding a touch of sophistication and elegance. Additionally, it finds application in signage and display systems due to its high gloss finish and durability, ensuring that the signage remains visible and attractive for a long time, even in outdoor environments.

|  |

Q: What is the advantage of PVDF coating compared to other coatings?

A: PVDF coating has excellent weathering characteristics, making it more resistant to fading, chalking, and degradation caused by environmental factors, thus having a longer service life. Compared to other coatings such as polyester, PVDF coatings have better resistance to ultraviolet rays and chemicals, making them more suitable for outdoor applications.

Q: Can the panel be made in longer lengths than 5800mm?

A: The standard maximum length is up to 5800mm, but for specific projects, it is advisable to consult with the manufacturer regarding possible longer length options. Longer lengths may require special manufacturing processes and handling to ensure quality and avoid damage during transportation and installation.

Q: How to maintain the high gloss finish?

A: Regular cleaning with mild detergents and a soft cloth is sufficient to maintain the high gloss finish. Avoid using abrasive cleaners that may scratch the surface. It is recommended to clean the panel at least once every three months, or more frequently in areas with high pollution levels, to remove dirt and grime that can dull the finish.

Q: Is the panel suitable for use in coastal areas?

A: Yes, the PVDF coating provides excellent resistance to saltwater and salt spray, making the panel suitable for use in coastal areas. It can withstand the corrosive effects of the marine environment, maintaining its appearance and performance over time.

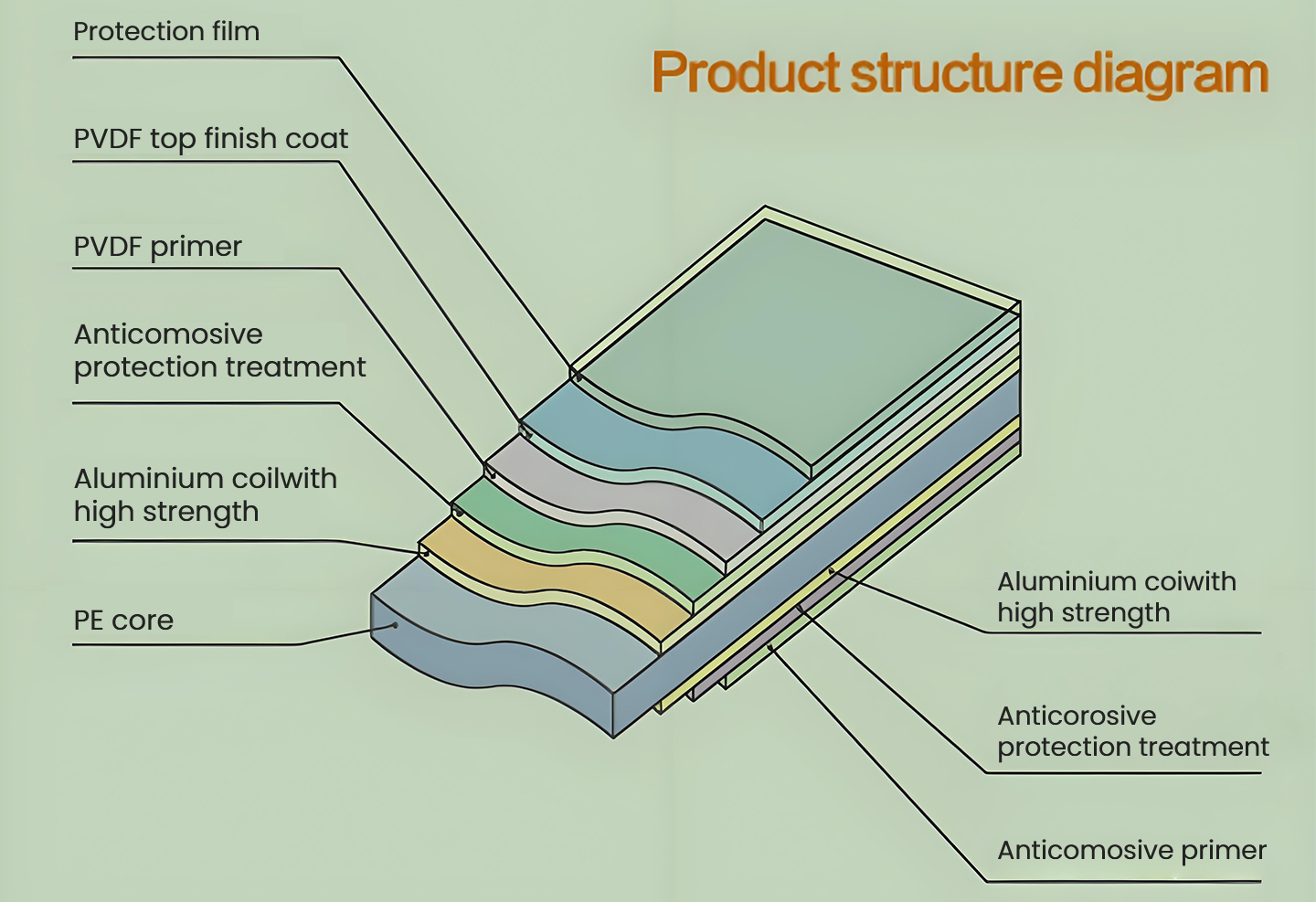

Cladding Aluminium Composite Panels PVDF Painting is an aluminum panel coated with PVDF (Polyvinylidene fluoride), featuring a high gloss finish that is achieved through a specialized coating process. The PVDF coating is applied using advanced techniques to ensure a uniform and smooth surface, resulting in a high gloss appearance that reflects light effectively. PVDF coating is known for its excellent weathering characteristics, making this panel a durable and visually appealing option for architectural applications. The aluminum base provides the panel with strength and formability, allowing it to be shaped into various designs while maintaining its structural integrity.

| Width | 1220mm, 1250mm, 1500mm |

| Length | Any size, recommend 2440mm, 3050mm, 4050mm, 5800mm |

| Panel Thickness | 3mm~6mm, recommend 4mm |

| Alu.Skin Thickness | 0.21mm~0.50mm, recommend 0.30mm and 0.40mm; |

| Alu. Alloy | AA3003(Different Grade Available) |

| Surface Treatment | PVDF/FEVE/NANO |

| Colors | Refer to Color Chart for more options |

| Others | Accept custom color and sizes |

Polyvinylidene fluoride that is also known as PVDF in short, is a type of fluorocarbon polymer resin used in architectural coating. PVDF coating is one of the preferred architectural coatings due to its excellent weathering characteristic of fluorinated materials

| Testing Item | Standard | Result |

| Coating Thickness | ASTM D1400 | 5µm Primer, 20µm Topcoat |

| Gloss | ASTM D523@60º | 23-35 |

| Pencil Hardness | ASTM D3363 | HB-H |

| Flexibility,T-Bend | ASTM D4145 | 1T-Bend; No pick-off |

| Solvent Resistance | ASTM D5402 | 100+ MEK double rubs |

| Adhesion | ASTM D3359 | No Adhesion Loss |

| Reverse Impact 1/16” Crosshatch | ||

| Reverse Impact | ASTM D2794 | 5.0J (0.6mm), No pick off |

| Acid Resistance | ASTM D1308 | No effect |

| Alkali Resistance | ASTM D1308 | No effect |

| Humidity Resistance | ASTM D714 | Passes 4000 hrs. |

The standard panel thickness is 4mm, with options of 3mm, 5mm, and 6mm. The coil thickness is 0.7/0.5mm as standard, with alternatives like 0.5/0.4mm and 0.5/0.5mm. The panel width is 1220mm standard, with options of 1250mm, 1500mm, and 1550mm, and the length is 2440mm standard, up to 5800mm. This wide range of specifications ensures that the panel can be used in a variety of architectural designs, from small feature walls to large curtain walls.

The PVDF coating provides excellent weather resistance, including resistance to ultraviolet rays, moisture, and chemicals. This ensures the panel maintains its high gloss finish and performance over a long period, even in harsh environmental conditions such as coastal areas with high salt content in the air or industrial areas with chemical pollutants. The coating also has good color retention, preventing fading over time.

The high gloss surface adds a modern and elegant touch to buildings, enhancing their visual appeal. It reflects light, making the building appear brighter and more spacious, and can also mirror the surrounding environment, creating a harmonious blend with the surroundings. The smooth surface is easy to clean, maintaining its glossy look with minimal effort.

This panel is widely used in high-end architectural projects. It is suitable for curtain walls of commercial buildings, hotels, and office towers, where a sleek and shiny appearance is desired to make a strong visual statement. It can also be used in interior decoration, such as feature walls and ceilings in luxury retail stores and restaurants, adding a touch of sophistication and elegance. Additionally, it finds application in signage and display systems due to its high gloss finish and durability, ensuring that the signage remains visible and attractive for a long time, even in outdoor environments.

|  |

Q: What is the advantage of PVDF coating compared to other coatings?

A: PVDF coating has excellent weathering characteristics, making it more resistant to fading, chalking, and degradation caused by environmental factors, thus having a longer service life. Compared to other coatings such as polyester, PVDF coatings have better resistance to ultraviolet rays and chemicals, making them more suitable for outdoor applications.

Q: Can the panel be made in longer lengths than 5800mm?

A: The standard maximum length is up to 5800mm, but for specific projects, it is advisable to consult with the manufacturer regarding possible longer length options. Longer lengths may require special manufacturing processes and handling to ensure quality and avoid damage during transportation and installation.

Q: How to maintain the high gloss finish?

A: Regular cleaning with mild detergents and a soft cloth is sufficient to maintain the high gloss finish. Avoid using abrasive cleaners that may scratch the surface. It is recommended to clean the panel at least once every three months, or more frequently in areas with high pollution levels, to remove dirt and grime that can dull the finish.

Q: Is the panel suitable for use in coastal areas?

A: Yes, the PVDF coating provides excellent resistance to saltwater and salt spray, making the panel suitable for use in coastal areas. It can withstand the corrosive effects of the marine environment, maintaining its appearance and performance over time.