Views: 0 Author: Site Editor Publish Time: 2026-02-10 Origin: Site

Are cheaper signs really saving money long term? This article compares ACM Panel Vinyl Signs and acrylic signs, explaining how material cost, durability, and maintenance affect real value and help you choose the smarter signage option.

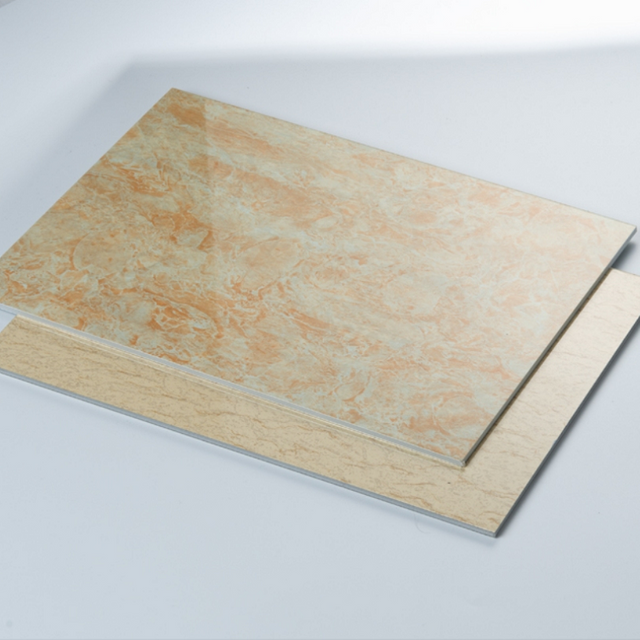

ACM Panel Vinyl Signs use aluminum composite panels made of two aluminum skins bonded to a stable core. This structure creates a rigid yet lightweight base, which matters when signs grow large. The smooth aluminum surface allows vinyl films to sit flat, helping graphics stay sharp and edges stay clean over time. For customers, it means fewer bubbles, less edge lift, and easier handling during installation.

From a practical angle, ACM Panel Vinyl Signs work well for both indoor and outdoor use. They resist warping during temperature changes and remain stable during transport and mounting. This stability supports long-term signage projects where replacement or rework would raise costs later.

Key characteristics:

● Lightweight structure that simplifies lifting and mounting on walls or frames.

● Rigid panel behavior that keeps vinyl graphics aligned.

● Clean, modern appearance suitable for storefronts and building signage.

Feature | ACM Panel Vinyl Signs |

Structure | Aluminum skins + composite core |

Surface | Smooth, vinyl-friendly aluminum |

Typical use | Large-format, indoor and outdoor signage |

Handling | Easy to cut, drill, and install |

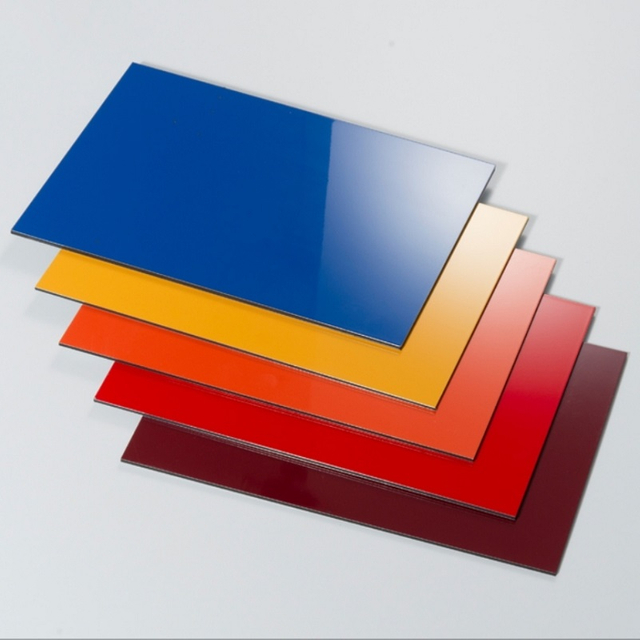

Acrylic signs use rigid plastic sheets that mimic a glass-like look. They feel solid and deliver a glossy finish, which appeals to customers seeking a modern, polished appearance. Acrylic works well for indoor environments where temperature and impact risks remain low. It supports creative shapes, layered designs, and illuminated effects, which explains its popularity in offices and retail interiors.

However, acrylic behaves differently under stress. It weighs more than ACM panels at similar thickness and can crack during transport or installation. For large signs, extra thickness is often needed to keep acrylic rigid, which increases cost and handling effort.

Material pricing depends on size, thickness, and rigidity requirements. Acrylic signs often look affordable at small sizes, yet costs rise fast when panels get larger or thicker. ACM Panel Vinyl Signs scale more efficiently because rigidity comes from their composite structure rather than material thickness. This keeps material usage lower for large signage projects.

From a budgeting view, ACM Panel Vinyl Signs offer predictable pricing for big formats. Acrylic pricing varies more due to thickness upgrades and finish options, which can surprise buyers later in the project.

Cost Factor | ACM Panel Vinyl Signs | Acrylic Signs |

Thickness need | Thin panel stays rigid | Thicker sheets often required |

Large-size pricing | More predictable | Rises quickly |

Waste risk | Low | Higher if cracking occurs |

Labor cost often exceeds material cost over time. ACM Panel Vinyl Signs are easy to cut, drill, and mount using standard tools. Their lighter weight reduces installer fatigue and speeds up positioning. This saves time during both fabrication and on-site installation, especially for wall-mounted or elevated signs.

Acrylic signs demand more care. Cutting and drilling require slower speeds to avoid cracking. Mounting takes longer due to weight and fragility.

Typical labor considerations include:

● Faster installation time using lightweight ACM panels.

● Reduced need for special handling equipment.

● Lower risk of breakage during mounting.

Transport costs change depending on material durability. ACM Panel Vinyl Signs handle vibration and stacking well, so they ship with lower damage risk. Acrylic signs need thicker packaging and careful spacing to prevent cracks or scratches. Any transport damage often means full replacement.

For customers ordering multiple signs, this difference affects total spend. Lower breakage risk means fewer delays and fewer replacement shipments, which keeps project schedules on track and costs controlled.

Outdoor signs face sun, rain, wind, and temperature swings every day. ACM Panel Vinyl Signs handle these stresses well because aluminum skins resist corrosion and the composite core keeps panels flat. Vinyl graphics stay smoother when the base does not flex, which helps color and edges last longer outside.

Acrylic signs can work outdoors, yet prolonged UV exposure and moisture increase the risk of fading, surface crazing, or warping. Many customers choose ACM Panel Vinyl Signs for exterior use because they keep a stable appearance across seasons and climates.

Weather Factor | ACM Panel Vinyl Signs | Acrylic Signs |

UV exposure | High resistance | Moderate resistance |

Moisture | Stable, non-absorbing | Can stress edges over time |

Wind load | Holds shape well | Needs thicker panels |

Impact resistance affects both safety and cost. ACM Panel Vinyl Signs resist dents and bending better than acrylic resists cracking. When signs get bumped during installation or public use, ACM tends to absorb force without breaking. Acrylic can crack from sharp impact, especially in cold weather. Over time, structural stability also matters.

ACM Panel Vinyl Signs keep their shape under load, which protects vinyl graphics from distortion and keeps mounting points secure.

Customers often notice these differences after installation:

● Fewer visible cracks or fractures on ACM panels.

● Better edge integrity during long-term use.

● Reduced need for reinforcement on large signs.

Maintenance frequency directly affects lifetime cost. ACM Panel Vinyl Signs need basic cleaning using water and mild detergent. The aluminum surface does not stain easily and vinyl graphics remain readable with minimal care.

Acrylic signs require more frequent cleaning to keep their glossy look. Scratches show easily, and improper cleaning tools can damage the surface, leading to higher upkeep costs.

Typical maintenance patterns include:

● ACM Panel Vinyl Signs cleaned a few times per year.

● Acrylic signs cleaned monthly in high-traffic areas.

● Higher repair costs when acrylic surfaces scratch or crack.

Service life shapes total ownership cost. ACM Panel Vinyl Signs often remain usable for many years outdoors, reducing replacement frequency. Acrylic signs usually have shorter lifespans, especially when exposed to sun or physical stress. Replacing signs more often increases material, labor, and downtime costs, even if initial pricing seems lower.

Aspect | ACM Panel Vinyl Signs | Acrylic Signs |

Typical lifespan | Long-term outdoor use | Shorter, environment dependent |

Replacement cycle | Infrequent | More frequent |

Long-term cost | Lower overall | Higher due to replacements |

Visual results start at the substrate. ACM Panel Vinyl Signs rely on a rigid aluminum composite structure, so vinyl films lay flat and stay aligned after installation. It helps graphics keep sharp edges and uniform color, even on large panels. Because the panel resists flexing, temperature changes cause less movement, which protects prints from ripples.

Acrylic can look glossy, yet larger sheets may bow slightly under heat or mounting pressure. That movement risks waviness in vinyl graphics and subtle distortion over time. Installers often compensate using thicker sheets, which raises cost and handling effort. For projects prioritizing clean graphics and consistency, ACM Panel Vinyl Signs reduce rework and visual defects.

Key print-related considerations include:

● Even vinyl adhesion across the entire panel face.

● Fewer bubbles and reduced edge lift during service.

● Stable color appearance after seasonal temperature shifts.

Print Factor | ACM Panel Vinyl Signs | Acrylic Signs |

Surface flatness | High and consistent | Varies on large sheets |

Vinyl adhesion | Strong and uniform | Sensitive to movement |

Long-term clarity | Maintained | Can distort over time |

Design goals influence material choice. Acrylic excels at layered looks, sculpted edges, and illuminated effects. It supports edge lighting and depth, making it popular for logos and interior feature signs. Designers often choose acrylic when lighting and shape drive attention more than scale or durability.

ACM Panel Vinyl Signs prioritize bold, clean surfaces and scale efficiency. They perform best for storefronts, building signs, and exterior branding where readability matters at distance. Instead of complex thickness or lighting, they deliver predictable fabrication and faster installation. This simplicity helps control budgets while keeping a professional appearance.

Design decisions usually balance:

● Clean, flat branding versus layered visual effects.

● Large-format outdoor visibility versus interior detail.

● Predictable costs versus creative lighting features.

Sticker price rarely reflects the true cost of signage over its full lifespan. ACM Panel Vinyl Signs often deliver stronger long-term value because they are built to last and require less ongoing attention. Their aluminum composite structure stays rigid and flat, which helps vinyl graphics maintain adhesion and appearance for years. When panels stay stable, graphics fail less often, and rework becomes rare. That stability translates into fewer installations, fewer schedule disruptions, and more predictable budgets.

Many buyers only recognize these savings after the second or third year of use. Acrylic signs may look economical at first, but they often require repairs or full replacement once cracking, warping, or surface damage appears. Manufacturers such as MC BOND design ACM panels with structural consistency in mind, helping customers reduce hidden costs across multi-year signage programs rather than just initial purchase expenses.

Ownership cost is usually shaped by several practical factors:

● Replacement frequency increases when materials crack, warp, or lose rigidity.

● Labor hours rise when signs need removal, repair, or reinstallation.

● Downtime affects branding when signs fail, fade, or look worn to customers.

Cost Driver | ACM Panel Vinyl Signs | Acrylic Signs |

Initial price | Moderate | Low to variable |

Maintenance | Low | Medium to high |

Replacement cycle | Infrequent | More frequent |

Long-term spend | Lower | Higher over time |

Value depends heavily on where and how the sign is used. ACM Panel Vinyl Signs fit permanent branding, exterior facades, and large-format displays where durability matters more than decorative depth. They hold shape outdoors, resist weather stress, and keep graphics readable from a distance. This makes them ideal for storefronts, building signage, and long-term brand installations.

Acrylic signs serve a different purpose. They work well for short-term promotions, indoor branding, or feature displays where lighting, layered effects, and visual depth take priority over lifespan. When used outdoors or in high-impact areas, acrylic may require more care and earlier replacement, which shifts total cost upward.

Buyers usually align their decisions around:

● Project duration and tolerance for future replacement.

● Indoor display goals versus outdoor branding exposure.

● Budget control versus preference for visual effects.

Choosing the right material early helps control costs later, ensuring signage continues to support branding goals without unexpected expenses.

This article compares ACM Panel Vinyl Signs and acrylic signs by cost and performance. ACM Panel Vinyl Signs offer durability, flatness, and lower long-term expense. Acrylic signs provide design freedom but need more care. MC BOND ACM Panel solutions deliver stable quality and reliable value.

A: ACM Panel Vinyl Signs use aluminum composite panels as a rigid base.

A: ACM Panel Vinyl Signs last longer and cost less over time.

A: Yes, ACM Panel Vinyl Signs resist weather and keep graphics flat.

A: ACM Panel Vinyl Signs cost less long term than acrylic signs.

A: ACM Panel Vinyl Signs need less cleaning and fewer repairs.