Views: 0 Author: Site Editor Publish Time: 2026-02-10 Origin: Site

Can one hidden layer decide how an ACM Panel performs in real projects? Many overlook the PE core, yet it shapes weight, flexibility, and durability. In this article, you will learn how PE core materials influence ACM Panel manufacturing and what that means for smart material choices.

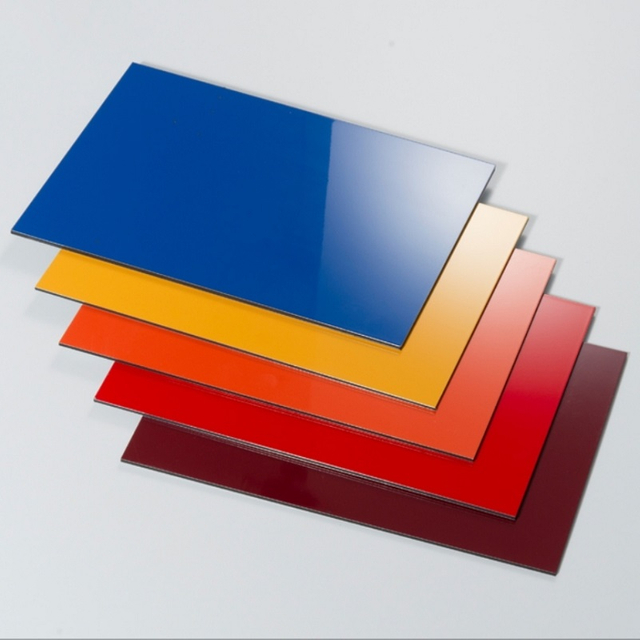

An ACM Panel is built as a layered composite rather than a single solid sheet. It uses two pre-coated aluminum skins bonded firmly to a polyethylene core, forming a balanced sandwich structure. This design allows the panel to stay flat across large surface areas, even when exposed to temperature changes or long spans. Instead of relying on thickness for strength, the ACM Panel relies on how these layers work together, which improves rigidity without adding unnecessary weight.

From a manufacturing perspective, companies like MC BOND focus on precise bonding between aluminum and the PE core. This bonding process ensures consistent thickness, smooth surfaces, and stable performance during fabrication, installation, and long-term use.

ACM Panel Layer | Primary Function | Contribution to Performance |

Aluminum Skins | Surface protection and appearance | Flatness, corrosion resistance |

PE Core | Structural support and spacing | Lightweight rigidity |

Adhesive Layer | Permanent bonding | Long-term stability |

The sandwich structure is what separates an ACM Panel from traditional metal sheets. By spacing the aluminum skins apart using a PE core, the panel gains bending resistance similar to an I-beam concept. This means it can span wider areas without warping or sagging. The PE core keeps the aluminum skins evenly aligned, so stresses distribute across the entire panel rather than concentrating in one spot.

In real applications, this structure helps panels remain visually clean and structurally reliable. It also reduces the need for heavy sub-frames, which lowers overall project costs and simplifies installation.

The PE core acts as the functional center of the ACM Panel. It controls how loads move across the panel surface and how the panel reacts to handling, cutting, and bending. Because the core is lightweight yet stable, it allows the panel to maintain strength without becoming difficult to transport or install.

This balance is critical in everyday use. Installers can lift larger panels more easily, fabricators can route or fold them with precision, and designers gain more freedom without sacrificing structural confidence.

Weight reduction is one of the strongest advantages of PE core materials in an ACM Panel. Compared with solid aluminum sheets, panels with a PE core deliver similar surface strength at a fraction of the weight. This matters during shipping, on-site handling, and long-term building performance.

One major reason customers choose an ACM Panel is weight control. A PE core replaces thick solid metal, yet still supports the aluminum skins across wide spans. It spreads loads evenly, so the panel resists bending while staying easy to handle. We see this advantage clearly in logistics, where lighter panels reduce fuel use and simplify site movement. For manufacturers like MC BOND, controlling PE core density helps deliver consistent panel behavior from factory to jobsite.

From a practical view, lighter panels speed up installation and reduce stress on substructures, which matters in both interior and exterior projects.

Material Type | Relative Weight | Installation Impact |

Solid Aluminum Sheet | High | Heavy lifting, stronger framing |

ACM Panel with PE Core | Low | Faster handling, lighter support |

● Lower panel weight reduces labor fatigue during installation.

● Transportation costs drop when more panels fit per shipment.

● Structural loads on buildings remain easier to manage.

The PE core gives an ACM Panel its fabrication advantage. It allows routing, folding, bending, and curving without cracking the aluminum skins. Designers like this freedom because it supports clean edges, sharp folds, and smooth curves in one material system. Fabricators benefit too, since they can work faster using common tools.

In daily production, they notice how the PE core absorbs stress during shaping. It keeps panels stable while edges stay precise. This balance helps complex designs move from drawing to installation without compromise.

● Panels route cleanly for cassette and tray systems.

● Curved façades and column wraps become easier to achieve.

● Fabrication errors reduce because the core supports controlled bending.

Durability is another core function driven by PE materials inside an ACM Panel. The core does not absorb moisture easily, and it stays stable across temperature swings. In hot climates, it helps panels resist softening and deformation. In cold regions, it limits brittleness and cracking.

Combined with coated aluminum skins, the PE core supports long-term use in humid, coastal, or polluted environments. This reliability is why PE core ACM Panels appear in interiors, signage, and approved exterior applications worldwide.

● Stable performance across hot, cold, and humid climates.

● Strong resistance to moisture and many common chemicals.

● Reduced risk of warping or delamination over time.

Beyond structure, the PE core influences comfort-related performance. Inside an ACM Panel, it helps dampen vibration and airborne noise, which improves acoustic comfort in interiors. It also acts as a thermal buffer, slowing heat transfer between indoor and outdoor spaces.

For users, this means quieter interiors and more stable temperatures, especially in partitions, ceilings, and decorative wall systems. While it is not insulation by itself, the PE core supports overall building comfort when paired with proper design layers.

● Improved sound control in interior partitions.

● Reduced thermal bridging compared to solid metal panels.

● More comfortable spaces using lightweight panel systems.

When we compare ACM Panel options, the core material becomes a deciding factor. A PE core focuses on lightweight structure and fabrication ease, while fire-retardant cores emphasize safety compliance.

PE core panels behave differently in fire situations, so many regions restrict them to interior use or low-rise buildings. Fire-retardant cores, filled with mineral content, slow flame spread and meet stricter building codes.

Core Type | Fire Behavior | Typical Applications |

PE Core | Combustible, standard fire response | Interior walls, signage, low-rise facades |

FR Core | Reduced flame spread | Commercial exteriors, public buildings |

● PE core suits projects prioritizing weight and cost efficiency.

● Fire-retardant core fits safety-driven architectural requirements.

● Local building codes usually guide the final decision.

Cost often drives the initial selection of an ACM Panel. PE core panels remain more budget-friendly because their core material is simpler to produce and process. This lower material cost reflects directly in panel pricing, transportation, and installation. Customers working on large interior projects often find PE core panels deliver strong value without unnecessary expense.

However, higher-cost cores become necessary when regulations demand enhanced fire performance. In these cases, the added cost supports compliance, risk reduction, and long-term project approval rather than basic performance alone.

● PE core panels reduce upfront material costs.

● Lighter panels lower handling and installation expenses.

● Fire-rated cores justify higher pricing in regulated projects.

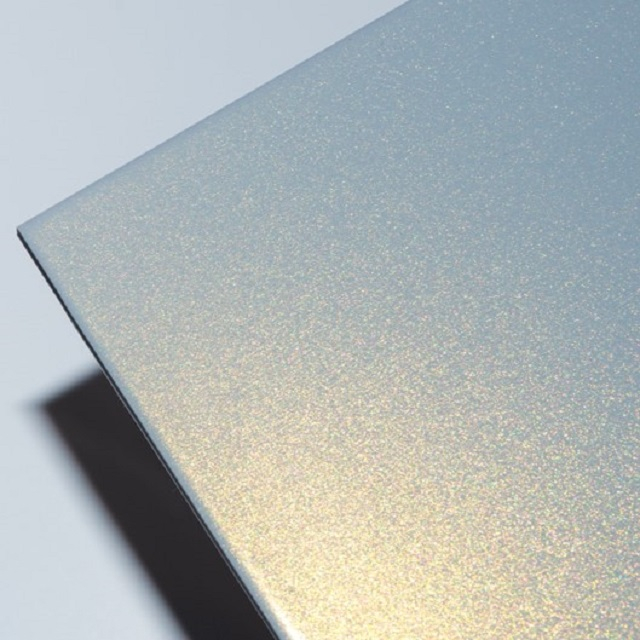

Every ACM Panel begins with aluminum preparation. Before bonding, aluminum skins go through cleaning and chemical pretreatment to improve adhesion. This step ensures coatings bond evenly and resist peeling during service life. PE core materials work well with common coatings such as PE or PVDF, supporting both interior and exterior finishes.

Good pretreatment improves surface durability and keeps panel appearance stable during fabrication, transport, and installation.

● Clean aluminum surfaces improve bonding reliability.

● Pretreatment supports long-term coating performance.

● PE core compatibility keeps panel structure balanced.

The PE core forms through controlled extrusion, then bonds to aluminum skins under heat and pressure. This lamination process fuses all layers into one stable ACM Panel. When temperature and pressure remain consistent, panels achieve uniform thickness and reliable strength.

In production, they watch lamination quality closely. Poor bonding can shorten panel lifespan, while strong lamination supports flatness and long-term performance.

● Heat activates bonding layers during lamination.

● Pressure ensures even contact across the panel surface.

● Stable lamination improves resistance to delamination.

Quality control keeps each ACM Panel consistent. Teams measure thickness tolerance, test adhesion strength, and inspect surface flatness. These checks prevent defects such as warping or separation between layers.

Manufacturers also simulate real conditions, checking how panels respond to temperature changes and mechanical stress.

● Thickness control ensures visual consistency.

● Adhesion testing reduces long-term failure risk.

● Surface inspections protect fabrication and installation quality.

From a practical viewpoint, a PE core ACM Panel fits applications where light weight, clean surfaces, and easy fabrication matter most. Interior wall cladding benefits from smooth finishes and stable flatness, which helps maintain visual consistency across large areas. Decorative systems use the panel’s flexibility to create folds, reveals, and crisp edges without heavy subframes.

In signage and advertising, the PE core supports large-format panels while keeping structures light. It handles routing and cutting well, so fabricators can deliver sharp graphics and fast turnaround.

● Interior walls gain a clean, modern look using lightweight panels.

● Decorative features benefit from easy shaping and precise edges.

● Signage systems stay rigid while reducing overall structure weight.

Application Area | Why PE Core ACM Panel Works | Practical Benefit |

Interior Cladding | Flatness and smooth coating | Clean visual continuity |

Decorative Systems | Easy routing and folding | Design flexibility |

Signage & Displays | Lightweight large panels | Faster installation |

Project scale often decides whether a PE core ACM Panel fits best. Low-rise buildings and interior-focused projects value speed, cost control, and handling ease. PE core panels reduce lifting demands and simplify substructure requirements, which keeps schedules tight and predictable.

Across global markets, climate also plays a role. In humid regions, the core resists moisture absorption. In hot or cold areas, it remains dimensionally stable for typical interior and approved exterior uses. Teams evaluate codes first, then match panel choice to scale and environment.

● Low-rise projects benefit from lighter façade loads.

● Interior projects prioritize ease of installation and finish quality.

● Climate checks ensure long-term performance expectations.

MC BOND integrates PE core options into its ACM Panel range by controlling core density, bonding consistency, and coating compatibility. Standard PE core panels target interiors and signage, while alternative cores address projects needing higher fire performance. This structured range helps customers choose quickly without over-specifying materials.

Quality systems align PE core selection with international standards, supporting stable supply and predictable results. Certifications and routine testing back the performance customers expect, whether panels ship to Europe, the Americas, or Asia.

● Standard PE cores focus on cost-efficient applications.

● Fire-rated options address regulated project needs.

● Certified processes support consistent global delivery.

PE core materials define how an ACM Panel balances weight, flexibility, durability, and cost in real applications. They support flatness, easy fabrication, and stable performance for interiors, signage, and approved low-rise projects. Through controlled PE core selection, precise manufacturing, and certified quality systems,MC BOND delivers ACM Panel solutions that help customers achieve reliable performance, regulatory alignment, and long-term project value.

A: The PE core supports structure, reduces weight, and improves fabrication efficiency in an ACM Panel.

A: A PE core ACM Panel stays lighter, lowers costs, and simplifies installation.

A: They are used for interior walls, signage, and low-rise ACM Panel applications.

A: The PE core resists moisture and helps ACM Panels stay stable across climates.

A: No, fire codes may limit ACM Panel use with PE cores in high-rise projects.